“So much is riding on your tires.”

That’s a slogan Micheline unveiled more than 30 years ago, and still uses today.

It was an ad geared at car owners, but the sentiment is true to anyone who drives: So much depends on having good tires.

If you’re a commercial truck owner, the right tires ensure your products get to where they’re going on time. And if you’re a commercial truck tire repair shop, you need to know that vehicles are leaving your facility prepared for the road, keeping truckers – and the drivers they share the road with – safe.

All the work you do on the tires you repair needs to adhere to the strictest safety standards, whether you’re patching or inflating tires, or fastening wheels to their hubs.

All the work you do on the tires you repair needs to adhere to the strictest safety standards, whether you’re patching or inflating tires, or fastening wheels to their hubs.

Virtually every tire job requires you to unfasten the tire from the hub, and the lug nuts you use must be tightened to a precise tension to hold properly.

Make the nuts too tight and they can damage the wheel, deform or warp. Make them too loose, and vibration can rattle them loose. This need for a specific torque for each nut makes properly calibrated torque wrenches an invaluable tool for commercial truck tire repair facilities.

And just as the different parts of a truck – brakes, suspension, transmission, etc. – undergo wear and tear and need regular service, so too do your torque wrenches.

If a torque wrench goes unexamined too long, it can lose calibration. Once that happens, it will deliver the wrong amount of torque with each use, putting drivers at risk.

How often should my torque wrench be calibrated?

Many industry professionals recommend calibrating torque wrenches after 2,500 repetitions, based on the idea that a wrench’s performance begins to become affected at the 2,500 to 3,000 repetition mark.

Many industry professionals recommend calibrating torque wrenches after 2,500 repetitions, based on the idea that a wrench’s performance begins to become affected at the 2,500 to 3,000 repetition mark.

Some things to consider about calibrated torque wrenches:

- Although many professionals don’t schedule their calibrations by the calendar, getting your wrench calibrated twice a year doesn’t hurt.

- Consider re-calibration if the torque wrench meets or exceeds 25 percent of its overload limit or if you’re seeing errors beyond the accepted limit.

- A good rule of thumb: the more you use a wrench, the more calibration you’ll need.

If it’s time to calibrate the wrenches at your commercial truck tire repair shop, Maxpro can help.

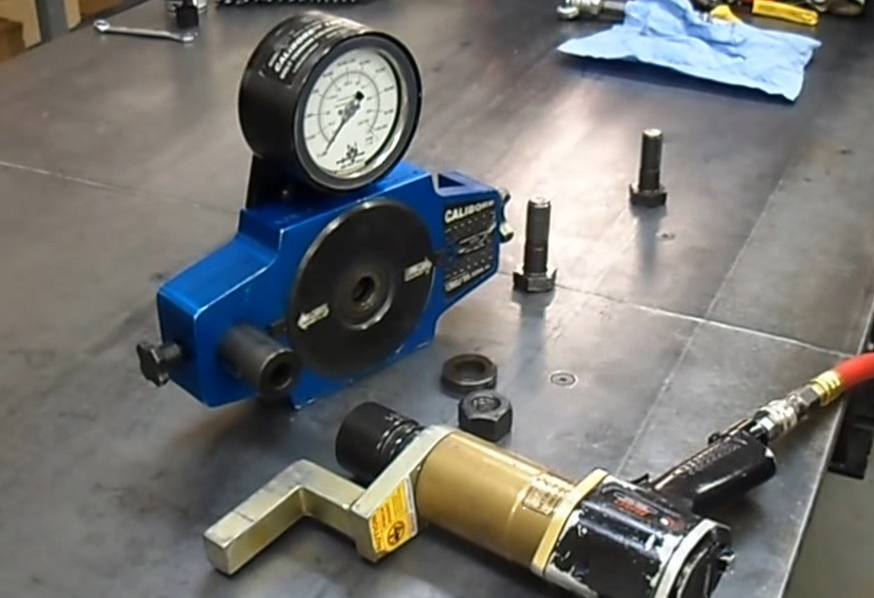

We take great pride in the investment we’ve made in cutting edge certification and calibration technology. Our clients count on us to take care of their equipment as we complete calibration to their satisfaction, using NIST traceable certifications on every calibrated torque wrench.

Our services can handle:

- Torque transducers from 0 to 6,000 ft. lbs.

- Torque wrenches from 50 to 50,000 ft. lbs.

- Pressure gauges from 0 to 10,000 PSI.

- Hydraulic, pneumatic and electric wrenches

Maxpro handles calibrations for hydraulic torque wrenches, electronic torque wrenches, pneumatic torque wrenches, adjustable clicker torque wrenches and pressure gauges.

If your torque wrench is ready for calibration, contact us today. We look forward to making sure you have the tools to keep drivers safe out on the road.