A325 and A490 are high-yield structural bolts used mostly in applications for bridges and steel-framed buildings.

These bolts have specific load/tension requirements per their ASTM specifications. But what about torque?

That’s a question we get quite often here are Maxpro: What is the torque required for the bolts?

This always leads to a discussion with the customer on the difference between required bolt load (tension) and torque (applied force).

And that leads to another question: Do we need torque or tension for these bolts?

The answer is: Yes and yes. You need both torque and tension for structural bolt tightening.

Torque or tension: What’s the difference

Load is the clamping force of the specific grade of bolt that has been determined to “hold the joint together” for the optimal design of that bolt.

Load is the clamping force of the specific grade of bolt that has been determined to “hold the joint together” for the optimal design of that bolt.

Torque is the applied force that will produce that load. A good way to think of it is this: “Load is the bolt”, “and torque is the tool applying the load.”

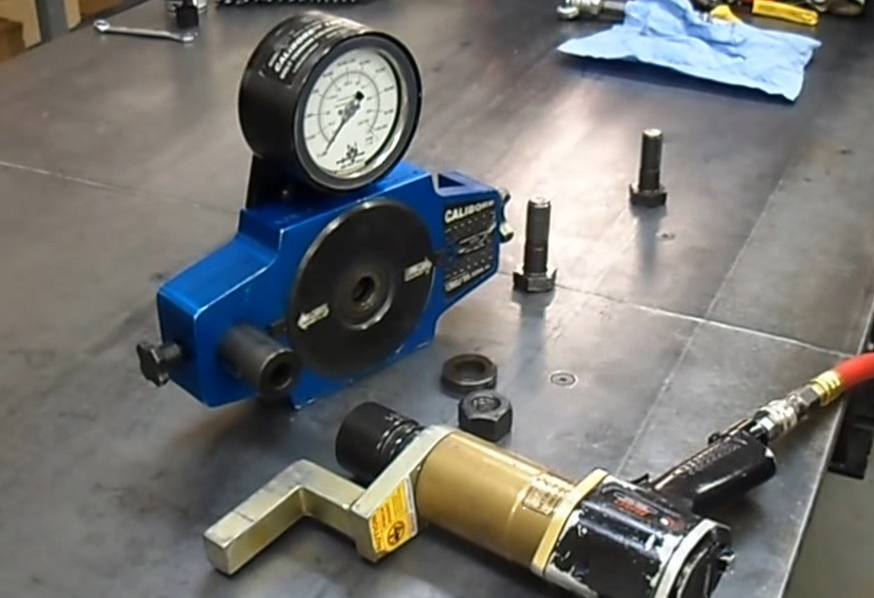

When testing bolt load, use a Caliborne Skidmore load verification stand with a calibrated and repeatable torque tool such as a RAD pneumatic, battery or electric torque wrench. It’s critically important to use a calibrated torque tool when tightening the bolts.

Applying the appropriate torque to bolts and verifying that the tool that applied the torque was correctly calibrated is essential for structural bolt tightening and for running a safe, effective plant or job site.

ISO 17025 and proper torque calibration

Developed in the 1990s, ISO 17025 is a standard for showing that a calibration lab is operating in a technically proficient manner using a documented quality system to generate accurate results. In our industry, ISO 17025 is considered the foremost standard for calibration labs.

Developed in the 1990s, ISO 17025 is a standard for showing that a calibration lab is operating in a technically proficient manner using a documented quality system to generate accurate results. In our industry, ISO 17025 is considered the foremost standard for calibration labs.

The standard’s creators wanted to provide competent measurement services and traceable results. The lab and its client agree on the services provided, and the validity of the testing and calibration is regulated by internal quality standards. Labs can demonstrate their competency through accreditation.

When you choose a lab that calibrates according to ISO 17025, you know that they’re a lab that:

Adheres to a formal, written quality program for all processes and procedures

Adheres to a formal, written quality program for all processes and procedures- Provides formal training in ISO 17025 processes

- Has its results checked and audited by an outside accreditation group, such as A2LA

In addition, ISO 17025 calibration offers peace of mind that:

- The employees performing the calibration are fully trained and qualified

- A written procedure is followed for every calibration

- Environmental factors are being monitored and maintained

Why Impact Tools Are Not a Good Idea for Torque

Impact tools do not have a repeatable torque specification. They should only be used for loosening bolts, not tightening.

The torque wrench will apply the repeatable torque required for the bolt to achieve the required load specification. Even when using “squirt/crush” washers, we recommend a calibrated torque tool.

Bolt testing on the Calibore should be done daily and adjusting of the torque wrench should follow this testing. For more information, please consult our torque and tension specification chart, which details the minimum and maximum bolt tension.

Bolt testing on the Calibore should be done daily and adjusting of the torque wrench should follow this testing. For more information, please consult our torque and tension specification chart, which details the minimum and maximum bolt tension.

Please note that this chart is only a guideline for structural bolt tightening. You should also be aware of factors such as changing weather, bolt lubrication, and other engineering variables.

Readers might also find the following document helpful for further research into this subject – Specification for Structural Joints Using ASTM A325 or A490 Bolts. This document was prepared by RCSC Committee A.1 – Specifications and approved by the Research Council on Structural Connections.

If you’d like to know more about our Calibore equipment and our extensive catalog of calibrated torque tools, please contact Maxpro. We’re confident we have the right tool for your next job.