A gasket in a joint is only as good as the force holding it in place. And when a gasket fails, the consequences can be as severe as the utter failure of a machine or system, leading to lost productivity, equipment damage, and compromised workplace safety.

In this blog post, we’ll look at some of the common reasons for gasket failure, which include:

1. Internal pressure

1. Internal pressure

This occurs when force works against the seal in two places: blowout pressure against the gasket, and hydrostatic end force against the joint, trying to push the flanges apart.

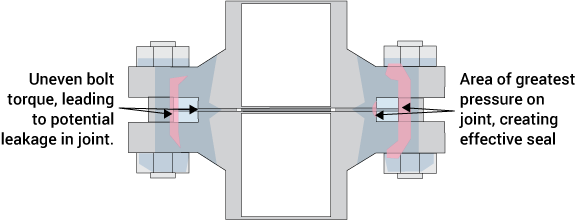

When the joint in question is over-torqued, the flange load can become uneven and weaken the effectiveness of the flange/bolt load. This in turn leads to an increase in blow-out pressure and hydrostatic force, which can cause joint failure.

2. Medium

The liquid or gas that the gasket is sealing can have a corrosive effect on the gasket material.

3. Temperature

Temperature changes can cause the metals in the joint to expand or contract, which makes the gasket either too relaxed or too compressed.

4. Flange load

4. Flange load

This is the pressure compressing the gasket to make a seal because of bolt loading. Bolts need to be tightened according to a certain sequence and the appropriate toque measurement.

Failure to adhere to this sequence, or to tighten the bolts correctly, can lead to an uneven loading of the flange faces, creating weaknesses where blow-out and hydrostatic pressures will have the most impact on the gasket.

Other common causes of gasket failure include:

- Misalignment of the gasket

- Misaligned flanges

- Improper bolt selection

- Improper application selection

- Erosion and permeation

As we said above, proper torque can be crucial to preventing gasket failure. For nearly 25 years, Maxpro has helped clients make sure they were working with quality, accurate torque wrenches.

We are proud of the investment we’ve made in innovative calibration equipment, and carry an accreditation from A2LA, the nation’s leading ISO/IEC accreditation organization.

Contact us today to learn how Maxpro can help you avoid gasket failure on your next project.