Every day, you’ll find more than 2 million tractor trailers on America’s highways.

When you’re in our industry, you see that statistic and immediately start to think about things like truck wheel bolt torque.

For truck owners and anyone responsible for servicing the wheels on those vehicles, it’s critical to make sure that proper torque is applied when installing the wheels.

In this blog post, we’ll look at the reasons why truck technicians fail to apply proper truck wheel bolt torque, and why calibrated torque wrenches are the best tool for ensuring safety on the road.

Proper torque for truck wheels

Proper torque for truck wheels

Every year, there are numerous American highway fatalities connected to ‘wheels-off” incidents involving trucks. Many of these accidents could have been prevented had proper truck wheel bolt torque been applied.

Unfortunately, too many truck and wheel shops take shortcuts when installing truck wheels. It comes down to two mistakes these shops are making:

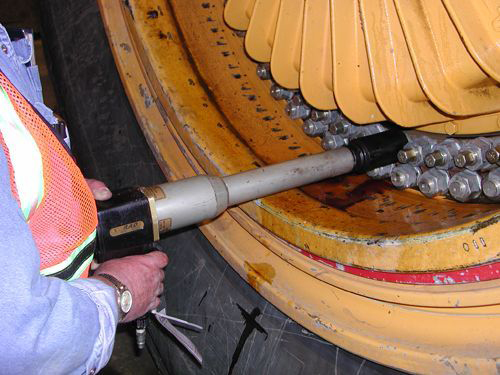

1. Use of incorrect tools to tighten the lug nuts on wheels

The number one tool used on wheel nuts in the trucking industry is the impact gun. But these aren’t torque-regulated tools, and thus often over-torque the bolts on the wheel, causing the bolts to be overloaded.

2. Failure to properly calibrate the torque wrench used to tighten wheel bolts

But not every shop uses the incorrect tool. Many will employ torque wrenches, the proper tool for ensuring truck wheel bolt torque.

However, not all of these wrenches are calibrated by an ISO 17025 accredited calibration lab, or in some cases, not calibrated at all.

It’s not uncommon for truck and tire shops to receive visits from a tool truck to have the torque examined on their torque wrenches.

Three questions that should be asked during those visits to ensure proper truck wheel bolt torque are:

Three questions that should be asked during those visits to ensure proper truck wheel bolt torque are:

- When was the checking transducer calibrated?

- Does the person checking the wrenches have training?

- Is there an ISO 17025 accreditation behind this torque check?

Substandard tool/torque practices should no longer be tolerated in this critical industry. We think it’s time for the National Transportation Safety Board to demand all commercial companies in the truck wheel industry require that all torque wrenches be calibrated by an accredited ISO 17025 company.

The truck wheel bolt torque issue is especially important in light of the proposition of highways crawling with driverless trucks. Most truck drivers will at least check their tires and wheels each time they stop for fuel or food. Driverless trucks will likely not have this same oversight.

When the safety of the public is at risk, proper documentation and certification can give you peace of mind. ISO 17025 provides you with that certainty.

Maxpro is an ISO 17025 accredited calibration lab, specializing in torque wrench calibration. Contact us today to learn how we can keep your trucks safe out on the road.