Many of the things that hold our world together are held together by bolts. And those bolts are firmly held in place thanks to proper tightening by industrial torque wrenches.

In this blog post, we’ll learn more about these invaluable tools and the types of jobs where they’re used.

What is an industrial torque wrench?

The torque wrench was invented in 1918 by a man named Conrad Bahr, who worked for the water department in New York City and needed a method of properly tightening bolts on water pipes.

Unlike the standard wrench, the torque wrench gave Bahr a tool that provided a specific level of torque to a fastener. These wrenches are useful on jobs where tightness is crucial. Users can measure torque to make sure it meets the specifications of the job.

What are the different types of industrial torque wrench?

There are four main categories of industrial torque wrench:

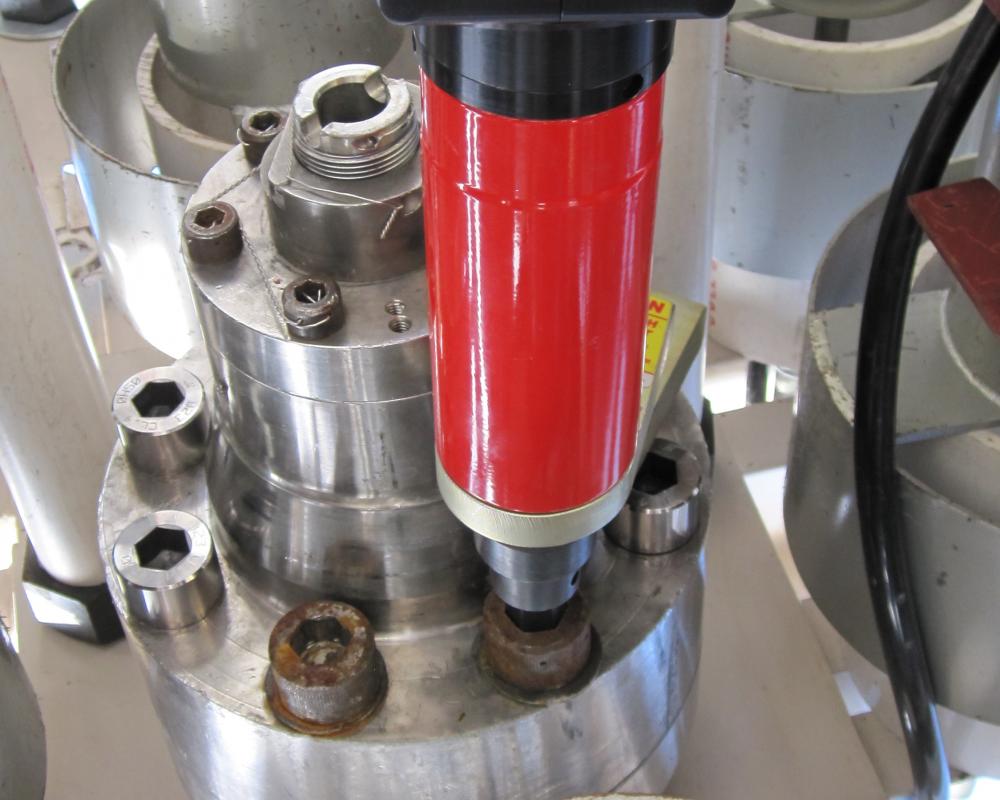

Hydraulic – Hydraulic torque wrenches use either an electrically or pneumatically-powered pump and can exert a powerful level of torque to large bolt heads. Because its power source is at the pump, the wrench can fit into smaller spaces.

Hydraulic – Hydraulic torque wrenches use either an electrically or pneumatically-powered pump and can exert a powerful level of torque to large bolt heads. Because its power source is at the pump, the wrench can fit into smaller spaces.- Pneumatic – These wrenches are durable

tools that work well in applications where flammable liquids or gases are present, such as mines or gas and oil pipelines. Pneumatic torque

wrenches are good tools for when you need to work quickly. - Electric – More accurate than

pneumatic wrenches, electric torque

wrenches will work any place that has a power source. They also feature data readability, giving users a print-out that details each job the wrench

has performed.  Battery-powered

Battery-powered

– These tools have come a long way in the past few years. Battery torque wrenches allow users to work without a power cord and come with electronic features not found on other torque wrenches. But they’ve also gotten lighter, with longer-lasting motors and batteries.

How are industrial torque wrenches used by businesses?

You’ll find industrial torque wrenches at work in a number of different

industries, including:

1. Wind Energy

It takes more than a thousand bolts to hold a wind turbine together, which is why electric torque wrenches are the choice of professionals in this industry.

It takes more than a thousand bolts to hold a wind turbine together, which is why electric torque wrenches are the choice of professionals in this industry.

But you’ll also find hydraulic wrenches being used in the wind industry, where they’re used to tighten and loosen bolts on the base of wind turbines. They’re also good for fastening bolts on turbine blades and gear boxes.

Wind speeds are projected to pick up over the next few decades – according to a recent Princeton University study – which is good news for the wind industry, and for industrial torque wrench makers.

2. Mining and quarry operations

Industrial torque wrench makers design their tools for tough environments such as mines and quarries, where they’re responsible for jobs like:

Industrial torque wrench makers design their tools for tough environments such as mines and quarries, where they’re responsible for jobs like:

- Bulldozer track maintenance

- Motor and gear box maintenance for conveyor systems

- Undercarriage servicing, track maintenance and side frame removal and electric rope shovels Track maintenance for hydraulic excavators and blast hole drill rigs, and upper rail maintenance on drag lines.

Again, because torque wrenches are designed to work in smaller spaces, they are an ideal tool for mining applications.

3. Power generation and pipelines

These industries demand tools that are both accurate and durable. Industrial torque wrenches can take on several different applications:

These industries demand tools that are both accurate and durable. Industrial torque wrenches can take on several different applications:

- Both oil exploration and oil production operations rely on hydraulic torque wrenches for wellhead connections, including BOP, valves and flow lines.

- Torque wrenches are used to assemble flanged joints, pipelines and valves at pumping stations and compressor stations, as well as for general maintenance).

- Nuclear power plants employ torque wrenches for bolting casket covers and general maintenance.

- There are numerous bolting applications at work at oil refineries: tightening or loosening bolts on a condenser and other equipment: heat exchangers, reactor covers, pressure pipe flanges, steam pipe flanges, valves and reactor pressure vessels.

Does your job require an industrial torque wrench? Do you need to make sure your wrenches are giving accurate readings? Maxpro can help on both fronts.

For more than 25 years, customers have relied on us as a supplier of both top quality torque wrenches – we carry tools from RAD in the hydraulic, pneumatic, electric and battery-operated versions – and a trusted calibration lab.

Contact us today to learn more about our tools and capabilities. No matter your industry, we’re confident we have the industrial torque wrench to meet your needs.