The American Society of Mechanical Engineers (ASME) is a non-profit organization made up of engineers, scientists and business executives working to improve their industry.

To that end, ASME has produced recommended industry standards based on research and testing. In this blog post, we’ll look at one of those standards, ASME PCC-1.

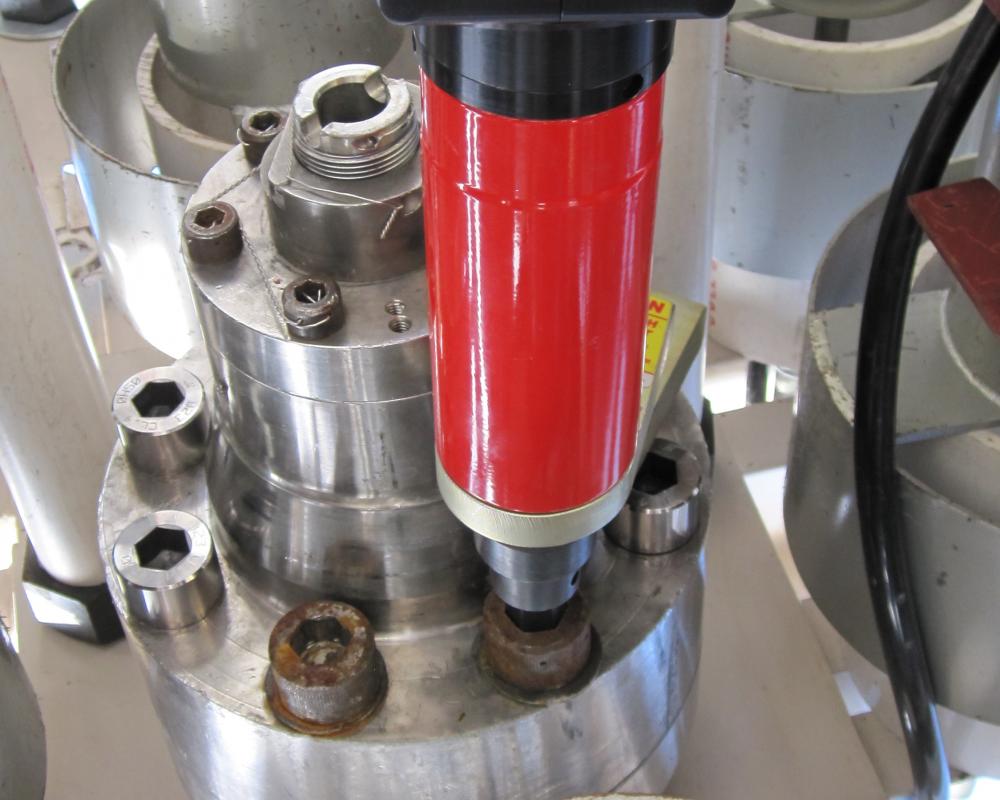

ASME PCC-1 is the guideline for pressure boundary bolted flange joint assembly. Essentially, anyone involved in the refinery, chemical and pipeline industries who deals with assembling bolting connections should be aware of this document.

While PCC-1 is a guideline, it is considered the standard for bolting joint connectors. Many major petro-chemical companies use this standard or are at least close to fully implanting it.

However, there is a key component of this standard that tends to be overlooked: “Training & Qualification of Bolted Joint Assembly Personnel.”

The complete PCC-1 document is more than 100 pages of processes and procedures including:

- Examination of flanges and surfaces

- Alignment of flanges

- Installation of gaskets

- Installation of bolts

- Torque and load determination

- Record keeping

- Proper tool selection

- Calibration of equipment

These are all important topics, but meaningless without proper training. The training and qualification section of PCC-1 details what ASME believes are the requirements for becoming a qualified bolting technician.

These are all important topics, but meaningless without proper training. The training and qualification section of PCC-1 details what ASME believes are the requirements for becoming a qualified bolting technician.

The training document is highly detailed, covering every aspect of safe and proper flange bolting. It includes testing and qualification as well as determining different levels of expertise.

Companies and contractors need to adopt a formal training and qualification program for their personnel who work on high pressure bolting connections.

This is critical to the safety of these workers, the plant and the surrounding areas. Leaking flanges are one of the prime causes of explosions and environmental disasters. And when a bolted flange joint issue occurs, the first question anyone asks is always “Was the technician properly trained?”

Proper training is important when working with bolted joints. So is proper certification. When you work with Maxpro, you can always be confident that you’re working with tools that were calibrated in an A2LA-accredited lab.

We specialize in torque wrench calibration and work with companies in several critical industries, including petro-chemical, refineries and mining.

Contact us today to find out how our lab can help your workers do their job.